|

It's February 1st, we are well into 2020 and ready to go! Even though it's cold out and everything seems dormant, there is much activity on the Jamison Family Farm. Haying will soon be upon us. Spring will come fast and we are working hard in advance to make First Quality Hay. We have fertilizer on order and will take delivery of it late this month. Today, I picked up some surfactant - which, in simple terms, is mixed with herbicides to help it stick to the weed leafs, penetrate their waxy coating and enable a more effective kill such that we can have weed free hay to the extent possible. We are going to rebuild or replace our present sprayer - as the tank is small and beginning to crack. The boom length is perfect for our rolling fields (20 foot spread) and so it is possible we might build our own sprayer frame, acquire a new/larger tank and adapt the booms, pump and controls from our old sprayer to it. One of the things we are very keen on with respect to spraying is drift. We are mindful of temperature inversions and use air induction type nozzles that are designed to effectively deliver the herbicide from the sprayer to the plant with minimal drift. We are also judicious with our herbicide selection. We rotate year to year between herbicide types to help prevent the weeds from becoming resistant to any one herbicide. None of the herbicides we use have a residual that carries over to our hay, to your animals, into their manure, that if not disposed correctly, could wipe out someone's garden or flowers if recycled as fertilizer. On the Jamison Family Farm, we have some beautiful hay fields, however, some of the timothy on these fields is getting aged. When I say aged, I don't mean 15 or 20 years old, but more like three to five years old. Our farm is situated on the southern edge of where one can grow timothy, so between the heat, occasional drought and competing pressure from a legacy seed bed of grasses, the timothy begins to die off. Were we not in the Virginia mountains, I'm not sure timothy would work as well for us as it has. I'm told that a "pure" stand of any grass is considered, worse case, an 80/20 percent ratio; 80 percent timothy and 20 percent other grasses for us. Once the mix grows beyond that ratio, we call it a timothy mixed grass hay. If managed correctly, this mixed grass still makes for very good horse quality hay. Some customers want straight timothy, others don't care; they desire a good quality, weed free hay and a timothy mixed grass hay is perfect. Timothy or mixed, we forage test all of it. The down side of a naturally occurring mixed grass hay is not the quality, but quantity. Just because the timothy is dying doesn't mean another grass will automatically take it's spot and you find the density of the stand lower and lower each year. We are in the hay business to produce as much hay as possible and in as much as we are moving our equipment across the field anyway, why not maximize yield to the extent reasonably possible. To slow the deterioration of the timothy, we over-seed in the fall to reinforce our stand, but at some point you have to start over. Enter Teff... Teff is an Ethiopian grain that has made it's way into the United States as a forage crop. It is a fine stemmed grass that is an annual - you have to plant it every year. As we rotate out a failing timothy field or bring on a new hay field that we've taken back from old pasture, we plant teff to realize revenue off that field until we can replant it in timothy. Some of you may know the qualities of teff, others may not. Teff is an excellent horse hay; it is on par with timothy and is a low carbohydrate hay. It is fast growing, requires lower inputs, but yields very well. For the hay producer, it is a love/hate relationship. Teff will not tolerate any frost and lodges easily. As previously mentioned, teff has to be replanted every year. When cut, one has to be careful as when you think it's dry and ready to bale - it is a good idea to wait another day as teff seems to rehydrate to some extent. When Teff clicks, it is the haymaker's dream. When it doesn't, it is the haymaker's nightmare. In 2020, we will be planting teff on at least one of our main fields and on the "10" in advance of starting over with straight timothy. In addition to some tractor and equipment maintenance, we are going to add at least two more kicker hay wagons. With our new barn, we have the space to park loaded kicker wagons of hay, up to 10 wagons, before the barn fills. This storage capacity and additional wagon count plays into First Quality Hay. We can now put more hay on the ground at a time, when the hay is at it's highest quality, get it into square bales, quickly off the field and into the barn - safely out of the weather. We have several running gears with rotted decks that are available for these new kicker wagons. As many of you know, there is a hay shortage. We sold out on January 1st. Prices are high, if you can find hay at all. We get emails and phone calls looking for hay every few days. I think if we had another 1,000 bales, they would sell easily between now and Spring. We appreciate all who have bought hay from us, look forward to your repeat business and hope other potential customers would consider our hay for 2020. Finally - in anticipation of haying come this Spring, May the Hay Dog is working hard to undo her winter fat. She is undergoing rigorous exercise so she can chase out any intruders (real or imaginary) that might otherwise compromise First Quality Hay. Take care and we'll talk again soon! The Jamison Family Disclaimer: This blog entry and all others are checked and edited by May the Hay Dog - woof!

1 Comment

Hay season on the Jamison Family Farm has ended for now and we are enjoying the fall colors and some much needed rain after a late summer drought. We had a record hay yield in 2019, but short of our potential. Second cutting hay was sparse as compared to first cuttings. To give a few examples, the Lower Field yielded around 1,200 square bales of hay on first cutting and second cutting yielded 99 bales. The Bull Pasture yielded around 300 bales of hay on first cutting and 15 on second cutting. We cut Crown Hill and didn't bother to rake it up to bale as the hay clippings were so thin. In spite of a lack luster second cutting, we had a very successful year. We are watching the weather between now and Thanksgiving. If moderate temperatures prevail, we see some growth and haying weather, we'll try to make a third cutting of hay. In the mean time, we are shifting gears to finish cutting firewood for the winter. We need about seven cords of wood to make it through spring. It seems that everyone says this winter will be especially cold, snowy and brutal, so we might add a another cord or two to the stock pile. All of our wood comes from dead and mostly downed trees. We never have a need to cut a green tree because every year, the wind, ice, etc., bring down enough trees to supply our wood. My boys are adults now and last time out, I gave each one of them a tree and chainsaw. Along with myself, we spent that weekend afternoon cutting firewood for several hours - enough time to run three to four tanks of gas through each saw; it made for a good showing of cut firewood. We cut as much as we can on an outing, leave it and haul it out another day to be split and stacked. We can cut now, but then have to wait during the freeze thaw period of the ground where everything is muddy, and can again resume cutting firewood after the ground is frozen solid. Our wood comes from "over the hill" and in/around the Bull Pasture. We are seeing some dead oak trees that have some kind of insect or fungus getting under the bark and killing the tree. The ash bore's are taking their toll too. Our preference is oak. Locus makes for a great firewood, but the downside of it, in my opinion, is when the wood burns down, it leaves behind large chunks of burnt charcoal (for lack of a better word) - impeding one's ability to re-fill the wood stove's firebox on the coldest of nights. Oak, on the other hand, burns down to a powder leaving plenty of room in the firebox for more heat producing wood. On the farm, as we browse around the woods, especially above the Saltpeter Field, we are quick to pick-up any "pine knots" laying on the ground for fire starting. When I was a boy, the deer hunting activities on the farm were impressive. We would pile up in the farm house with as many as three stoves going. A kitchen wood cook stove, a Warm Morning coal stove in the living room and a wood/coal stove in the "parlor" where there were two single beds and a foot pedal organ. Everyone kept a vigil eye out of the windows for a deer that never came, though someone would get lucky and kill a deer sometime during the two week rifle season "over the hill". We also listened at night to the radio, a Zenith Transoceanic. Those wood and coal stoves would burn hot, but not for long. It seemed we would "bank" the stove with the inside temperature at 80ish degrees, hit the sack in our briefs and no covers, wake up the next morning in all our clothes, coats and heavy blankets on top - watching our breath freeze as we exhaled. Cold feet were the norm. Speaking of hunting... I use to work at a local store in their sporting goods department. In it they sold all kinds of guns, fishing tackle, etc. I would write out hunting licenses for hours. I was NEVER a very good hunter or fisherman in terms of the "catch". I never killed a big buck or caught my limit of trout, however, behind that sporting goods counter, I might as well have been Curt Gowdy on the American Sportsman. Everyone thought that IF you worked at a sporting goods store (and in my case - I drove a 1970 4x4 International Scout 800A which added to the legend), you had to know the business. Customers would ask me - "what are the fish hitting on today?" I didn't have a clue - even on a good day, but I'd blurt out something like "those pink salmon eggs are the cat's meow". The customer would load up on four or five bottles and return later and tell me they caught their limit. Everyone killed an eight point deer and caught their limit and thought I did too, but I didn't. I never caught my limit or killed anything more than a doe - on doe day. Zebco made a set of fish scales called "The De-Liar" - I thought it an appropriate name for fish scales for the guys using pink salmon eggs and killing those 250 lb eight point deer. One time, I was behind the counter waxing about my hunting experience earlier that afternoon on Linton's Ridge at the farm. I was squirrel hunting at the top of it with my double barrel Fox 20 ga shotgun. There were four or five guys on the other side of the counter listening. I told about how I heard a rustling in the leaves behind me, looked around and it was a couple of turkeys - out of season, of course. I opined, that upon seeing those turkeys, I quietly broke down my shotgun, reached in my hunting vest (all Curt Gowdy watanabes wear hunting vests), plucked out a couple of buckshot shells, eased them into my side by side shotgun barrels and when I closed the gun, the barrels snapped shut with a loud click - the turkeys alerted to my presence took flight never to be seen again. When I finished this yarn, one of the gentlemen in the gang of four or five listening to my story kindly informed me that turkey season was not here yet and had I shot one of those turkeys, it would have been illegal. I said, "who are you?" He said, "I'm Judge so and so - who are you?" I said, "I'm the biggest liar in Alleghany County"... Back to the wood... Unlike the wood stoves we used on the farm, the wood stoves we use in our house are very high efficient, clean burning stoves. We have two wood stoves, one in our living room and one in our basement. The basement stove is an Englander NC30; I call it the heat bomb. It can bring the basement up to 85 degrees in a jiffy. It is an all steel stove and uses secondary air injection to burn the gasses in the smoke. The wood stove in our living room is more elegant and softer with the heat. It is a Woodstock Keystone wood stove. It is made of a cast iron frame with soapstone sides and top. The soapstone absorbs the heat to dampen the heat spikes on the hot side and then as the fire dies down, the stored heat in the soap stone continues to radiate for hours - making for soft even heat throughout the burn cycle. The Keystone uses a catalytic converter element to burn the gasses in the smoke. The chemical reaction of the elements on the catalytic honeycomb substrate lowers the temperature at which these exhaust gases will ignite. This allows for long burns at lower stove temperatures - especially nice on warmer days or when the stove is "banked" for the night. In the coldest of winter, it is not uncommon the Keystone to burn continuously for weeks - only emptying the ash pan and re-filling the stove with wood. When the above wood stoves are burning to a given stove top temperature (read sweet spot), there is no visible smoke out of our chimneys. It is as though there is not a fire in the house. In addition, the amount of creosote in our chimneys is minimal. However... In keeping with the title of this blog, here are a few fall pics around the Jamison Family Farm... In the picture above, those black and green balls on the ground are walnuts. The Jamison Family Farm has many walnut trees around. When I was a boy, we use to collect a lot of those walnuts. Getting the husks off of them left one with black stained hands, so my Dad devised a way to rid the husks without the mess. He would dump the walnuts in our gravel driveway in the car tracks and after a week or so of running over those walnuts, the husks were gone and we could pick out the walnuts - hands stain free. In my Dad's basement workshop, there was a vice. Nearby was a ball peen hammer and we would set the walnuts on the anvil part of the vice and crack them open with the hammer. After smashing our formally blackened fingers with the hammer, we realized the power of vice jaws and set the walnuts in them, cranked down and enjoyed fresh walnuts for a snack... More fall pics... May the Hay Dog is enjoying the Fall down time from haying... If you are in need of First Quality Hay, we still have some timothy mixed grass hay from our first cuttings for sale. For more info, pricing or questions, drop us a note at [email protected]. Disclaimer: This blog entry and all others are checked and edited by May the Hay Dog... woof!

It's been a while since I made a blog entry - we've been pretty busy on the Jamison Family Farm over the past several months... The Hay... Last year we were plagued by rain and in many respects this year we experienced the same - but different. Last year, we got very good cuttings of what we could cut, but rain caused delays in other fields over a period of weeks causing us to bush hog some of those fields rather than harvest. In 2018 we also wrestled with equipment breakdowns which hampered our haying efforts. We struggled mightily with our dome shelters and their vinyl covered roofs. In contrast, this year, we were able to cut all of our fields, but rain and the threat of rain presented some challenges and delays; we had excellent service out of our equipment. Our fertilizer timing in conjunction with grass maturity and potential rain all clicked. We applied less fertilizer, yet harvested more hay per acre than in any previous year. As a result, our first cut yield is up 25% over all of our haying last year. Our herbicide application and timing were very good too. While we are seeing more and more orchard grass and fescue come into our timothy fields, I feel we have the weed situation under good control and are trying a new to us herbicide to control foxtail. For 2019, we are mashing our fields for a second and maybe a third cutting - something we really haven't done in the past. We have sprayed for broadleaf weeds, foxtail and have fertilized for these upcoming cuttings. I am hopeful we can begin a second cutting around the 15th of August and perhaps a third around September 15th - we'll see... Below are a few pics of our haying efforts. Not all of our hay is nice and green... We kind of think it's nice hay - but some of it is a bit tan. On our lower field cutting, we had rain the day after we cut. We quickly tedded out the hay several times to get it dry. We were further delayed in baling by the threat of rain for several more days than we would have preferred. We would be positioned to bale, only see dark clouds to appear, to hear thunderstorms nearby and literally smell water in the air. It's better to have the hay see rain in the windrow than to get bales soaked, so we would pass on baling and did so for several days. Ironically - each evening we attempted to bale and called it off due the threat of rain - yet it never rained on the farm. Driving up and down the road to the farm, we would see where it had rained, sometimes very hard and only a few miles away. The net effect of our delayed baling on the lower field was hay that was exposed to the sun for several days and with it some fading. However... We don't rely on just color, touch and feel (though important). We sample all of our hay cuttings and sampled the lower field in two halves. We have four fields and submitted five samples of hay to Equi-Analytical for analysis. We use their wet chemistry Trainer 603 test, all of which are back and again our hay is low in sugar (ESC+starch), potassium and iron. Testing in not inexpensive; the Trainer 603 test cost's $67.00 each (including the $2.00 postage fee). For our first cuttings, we spent $335.00 so we can show our buyer exactly what they are getting. I don't personally know of any other hay producer near us doing the same. Yes - color, touch and feel, absence of weeds, tight bales are very important considerations for one's hay, but we think First Quality Hay demands a food label and we provide it. If you'd like a copy of our hay test results, send us an email at [email protected] Above are core samples being taken and May the Hay Dog keeps things honest by taste testing our hay - when she can find it... The Barn... I think I've mentioned before that my kids are 5th generation on the Jamison Family Farm. My great grandfather, James Henry Jamison, built the barn that has seen use for over 100 years. My grandfather, George Lewis Jamison, made sure the fields were well fertilized and often the old barn was full to the top with square bales of hay. In James Henry's day, loose hay ruled. He built the original barn for horses, storage of loose hay and in the back was a manger for feeding cattle or sheep. The beams in the barn are held together with wooden dow pins. It originally had a wood shingle roof. That was replaced during World War II and my Dad helped with the replacement. Due to the material needs of the war, steel roofing was not available, so tin was used. The old barn always had a shinny roof. I recall my Dad telling me that it was fall when they replaced the roof and he was on top of the barn working. Directly ahead - across the road on the farm is Linton's Ridge. It is a wonderful and plentiful place to squirrel hunt. My Dad recalled that while he was helping with the roof - where he really wanted to be was on Linton's Ridge squirrel hunting. Sometimes my boys or my brother will kill a few squirrels and my mother will make a tasty squirrel pot pie! While the old barn served the farm extremely well, over the years it has been wearing and breaking down. The roof is coming loose; tin ripping away in the wind, roof supports with holes from bumble bees that bore into the wood, overloading the barn - designed for loose hay, yet packed with squares for over 50 years took their toll. Strong winds have caused damage and believe it or not, ground hogs digging under the barn have damaged the underpinnings of the barn causing it to sag in critical areas. Below are some recent pictures of the barn... As bad as the barn looks, some of it is still useable. Last year we filled every nook and cranny that was available for hay and if needed could still store some hay in the old barn. But this barn was built in a different time and as great as it is/was, it is not tractor/implement friendly for today's haying. All hay stored in the barn had to be carried inside for stacking; a tractor or wagon could not fit under it. If rain was coming, unloading was a real fire drill to get the hay off the wagons and into the barn and haying wasn't finished until ALL hay was unloaded and in the barn. Sometimes we were close to midnight getting hay off the wagons and stored. Bottom line - it was time to either rebuild the old barn or build a new one. Given our haying needs, I felt a new barn - one designed for haying that fits what we are doing in 2019 (and beyond) was a better option. Below are a few more pictures of the old barn. One is a picture of hay neatly stacked in the barn, another is with myself and Iva stacking some hay and finally my lush barn office... So with the decision made to build a new barn, a few thoughts permeated my head. To start with - this would be the first and last barn I'd ever build; it had to be a home run. This barn had to meet our haying needs - to include features that made it easier to work around our day job hours. It had to be built to a different standard - one that would help preserve and sell First Quality Hay. The New Barn... While this is a pole barn, it is not the ordinary pole barn one might see or use for hay. It is designed with three doors, one on each end and one on the side. The doors are 16 feet wide and 16 feet tall; they will have sliding doors covering the openings. The two end doors enable drive through and the barn is wide enough to turn in/out the side if necessary. This barn is 32 feet wide x 88 feet long with a clear span 16 foot interior height. It has two foot roof over hangs on each side and one foot overhangs on the ends. There are gutters along each long side to divert water away from the building. Most pole barns have metal roofing, so does ours, however, metal roofs are notorious for raining condensation onto the hay below. Sometimes a bubble or felt insulation is used to minimize this, but over time it generally fails to stick and peels off the underside. Our barn uses plywood under the metal roofing (with a felt barrier between) to provide additional strength to the roof, but also to serve as insulation - preventing condensation. A barn needs to breathe as hay sweats and continues to dry down after baling and air movement is critical. The two foot over hangs on each side of the barn are vented; the roof has a ridge vent too. There is a lot of air movement in this barn; even when we have the doors in place, this barn will breathe nicely. It's handy to have some natural light in the barn, so we designed-in clear polycarbonate panels under the eave's of each side of the barn. We want light, but not to much as it discolors the hay. We opted for continuous light panels down each side of the barn, but limited their height to limit to much light from entering the barn. The pic below shows those light panels from the inside... As I mentioned, the doors on this barn are 16 feet wide x 16 feet tall. The idea with these large doors was multiple. One of them was to have a barn door opening large enough to allow a tractor trailer to back-into for a load of hay. More importantly though, was a need to get hay baled, quickly into the barn and out of the weather for unloading later. These doors are large enough that until the middle of the barn fills-up with hay, we can pull our wagons right under it. This is a huge help when you are haying around a full time day job and/or just trying to beat the rain. Remember the old barn - everything had to be unloaded - regardless. The new barn: We park the wagons under it and unload later - when it's cooler, when it's raining or another day. There are no fire drills with this barn... We wanted a barn large enough to hold all of our present hay yield and future increased yields - as we continue to take back old pastures and convert them into hay fields. We actively manage our fields from depleted old pastures, lacking in just about everything, to strong hay producing acreage. On our first cuttings this year, we had one field that yielded 150 bales per acre. In contrast, a typical, wore-out/depleted field without any inputs on this farm, might make 40 bales per acre per year. So with the increased acreage and increased bales per acre, storage capacity is important. If we stack hay to the bottom of the trusses, we can put just over 6,000 bales of hay in this barn. It is unlikely we will ever get that many bales of hay in this barn at once - though anything is possible. Hay inventory ebbs and flows as we make our cuttings. We have already sold a fair amount of our first cuttings and are a couple weeks away from our second cuttings. Our short term goal is at least 5,000 bales per year (all cuttings) and that goal will be achieved in a few years. It's good to know we have a barn capable of holding that much hay. We no longer need our other sheds/shelters to store hay and the headaches (read loss of hay) that went with them. Color... We wrestled with what color this barn should be. Seems simple enough, but we spent a lot of time over the winter considering the look of the barn. As you can imagine, I've got this slickery website with nice pictures and when customers would pull into the farm, our shelters visually left something to be desired - to say the least. Ever look online at beach hotels only to book one based on how nice it looked in the pictures, but when you got there - maybe the hotel looked that good on one side, one time in the past, but in person - it was a dump? I kind of thought our old shelters, especially our dome shelters - while functional, did not convey a warm and fuzzy with respect to First Quality Hay... This new barn needed to look great AND sell hay... I thought I wanted a red barn with a silver or white roof - a traditional looking barn. We drove around looking at barns of every color, looked on the internet at pictures and you may not believe it - agonized over the color scheme. This is the first and last barn I'll ever build - it has to be right, down to the barn colors. We were 99% sure we were going red until we drove out from Sweet Springs West Virginia to Union. Along the drive we saw red barns, white barns, beige barns - some wooden barns that had never seen paint. What we did see was a few nice white barns with green roofs. Mindful the farm house is white with a green roof - at the last minute we decided to go with white sides, green roof and but added green wainscoting around the bottom. I'm a little biased, but against the mountain backdrop, I think our the barn color choice looks pretty good. Good enough to show the same barn picture from above - again... I can ramble more about this barn - ask me when you come for a visit or a load of hay... The MF... Over the years we have upgraded our equipment and the machines we use to cut our hay has evolved from a simple sickle mower to a sickle mower conditioner to a disc mower conditioner. If the sickle mower required 25 horsepower and the sickle mower conditioner required maybe 40 horse power, our disc mower conditioner (to realize it's fullest potential) requires 70 horse power minimum and in heavy hay, at a good clip, even more power. We also wanted a very heavy tractor such that when we have a loaded hay wagon, we can safely bring it down from the "hill" without being pushed to the bottom. As I mentioned in an earlier blog, we searched all winter for another tractor and settled on a Massey Ferguson 1105. This tractor has a 110 PTO horse power and weighs in at close to 15,000 lbs. It handles our mower conditioner like a dream. At 7 mph (our sickle mower conditioner on a good day made about 3.5 mph) and in heavy hay, I can mow four acres in one hour. The tractor mower combo makes it possible for me to arrive at the farm and mow late in the evening, into the dew and/or dark. The disc mower conditioner will not clog the cutter bar like our other sickle machines in dew damp hay or tangled lodged hay and plows right through everything leaving a golf course cut. MF has the power to run it as fast as I can stay in the seat and loaded hay wagons do not push this tractor around. The Massey Ferguson 1105 is a welcome addition. A few more pics... As I'm writing, it's getting late; about 2 am. I think this is the longest blog I've written yet. May the Hay Dog thinks it's a bit much and would like me to knock it off for the night... Hope everyone has a great Summer. If you are in need of good hay, additional info on our hay or have questions - send us a note to [email protected] Disclaimer: This blog entry and all others are checked and edited by May the Hay Dog... woof!

For God so loved the world that he gave his one and only Son, that whoever believes in him shall not perish but have eternal life. John 3:16 (NIV) Happy Easter from the Jamison Family!

We are glad to see Spring 2019 come to the Jamison Family Farm. With a break in the weather, we are very busy preparing for our 2019 haying. Equipment repairs and maintenance are underway; this past weekend, we finished fertilizing. Spraying for broad leaf weeds will come a bit later as they begin to grow into our hay. I posted the pic below on our Facebook page... The wind blew my hat into the fertilizer spreader and the spreader gave it - it's best effort to spread the hat, ouch! The fertilizer spreader is a Lely spreader; probably 50 years old. It is rusted at the bottom and on it's last leg. The charts are useless for metering fertilizer due to metal lost to rust - but we make do. My boys and I (several years ago) spread bags of fertilizer on each setting. We recorded the PTO rpms, width of spread, ground speed in MPH and the amount of time it took to empty the given amount of fertilizer. From this, we calculated pounds of fertilizer spread per acre. We still use 50 lb bags of fertilizer and based on our calculations, we can just about apply and come out of the field within one bag of having the exact amount. We could hire spreading of our fertilizer, but prefer to apply it ourselves; we want an exacting amount as prescribed by our soil sample recommendations based on expected yield. VA Tech does our soil analysis. Accurate fertilizing is important to making First Quality Hay. Below is a pic of one ton of nitrogen 46-0-0. Typically fertilizer is applied with respect to N, P and K - which is nitrogen (N), phosphorus (P) and potash (K). One can buy a blend, such as 10-10-10, but our soil recommendations never call for even amounts of N, P and K. So we buy each separate and apply as needed for each field. One would think that with all this gibberish regarding accurate metering of fertilizer on our fields via soil samples, calibrated spreader, etc., that we would use some kind of high tech GPS to guide our spread. I suppose we could, however, we have found that a drop of toilet paper here and there shows the way. Don't know if the Engineers at John Deere had it in mind, but the throttle lever on our fine JD 5055D has proven to be an excellent dispenser for the TP. We don't have GPS on the Jamison Family Farm, we have TPS! Other chores are building more kicker wagons. We expect to have six total wagons ready for haying this year. Each wagon holds at least 130 square bales and if we are good at tossing into the wagon, 150 bales. Best case, we should be able to move 900 bales of hay off the field as we bale without any field labor other than driving the tractor and changing out wagons. Above is a very good running gear we are stripping off the old deck and runners for a new life as a kicker wagon. We have plans to build a new barn that allows these wagons to be parked inside and at the same time for unloading later. The goal is to get the hay timely baled for First Quality Hay and out of any potential weather. Our new barn will let us unload - sheltered and dry. In years past, it could be a race to get the wagons unloaded before rain moves-in; this barn will be a welcome relief from that situation. We can put 130-150 bales on a wagon in as little as 20 minutes; a game changer when a thunderstorm is threatening and getting hay off the field and under cover ASAP is a must. If you've been on the Jamison Family Farm, you know it is divided by a highway. "Below the road" and "over the hill" are terms thrown about on the farm; you've heard them too. We have focused our efforts mostly on fields below the road, including the bull pasture and the 10. In addition we have a really nice stand of timothy over the hill on Crown Hill and the Orchard Field, however, there is much more acreage to be reclaimed and put into hay. To expand, our dilemma haying "over the hill" has been two fold, one - we need more hp than the mighty IH Farmall 756 Gasser can deliver to drive our Krone mower conditioner on these hills. The second challenge is to bring loaded hay wagons off these hills safely without being pushed to the bottom! Note - we would only hay on the ridge lines, tops and mild slopes - not the steep part you see in front of the tractor! The remedy is more hp and more weight; hp to sufficiently drive the Krone and massive weight compared to a loaded kicker wagon to resist push and maintain traction and control moving hay off the hill and to below the road. We have been shopping for a suitable tractor in multiple states over this past Winter; Ohio, Pennsylvania, North Carolina, Virginia, West Virginia and Kentucky - all of which we have traveled for a look-see at a potential tractor buy. For various reasons, none of the below made the cut... However, after much travel, effort and empty handed frustration, we finally found and bought another tractor - one suitable for haying "over the hill". It is 100 hp, has a cab, heat and AC. It will weigh-in around 13,000 lbs. If we put fluid in the rear tires, it will come-in at close to 15,000 lbs, almost 8 tons. We're not sure May the Hay Dog can wedge herself into the cab along with the driver for a command view... The tractor is not new and has about 4,800 hours; it is in excellent condition and delivers the mail on all points we set-out during our tractor purchase quest. This tractor is located in... Our "new to us" tractor will be trucked-in to the Jamison Family Farm sometime between now and May 1. I'd like to tell you what we bought, however... Stay tuned to our next blog where you will read... More info on this tractor, it's make, model and pictures. I'll give an update on our haying efforts unfolding over the next weeks and months - as we strive in 2019 to make First Quality Hay... Disclaimer: This blog entry and all others are checked and edited by May the Hay Dog... woof!

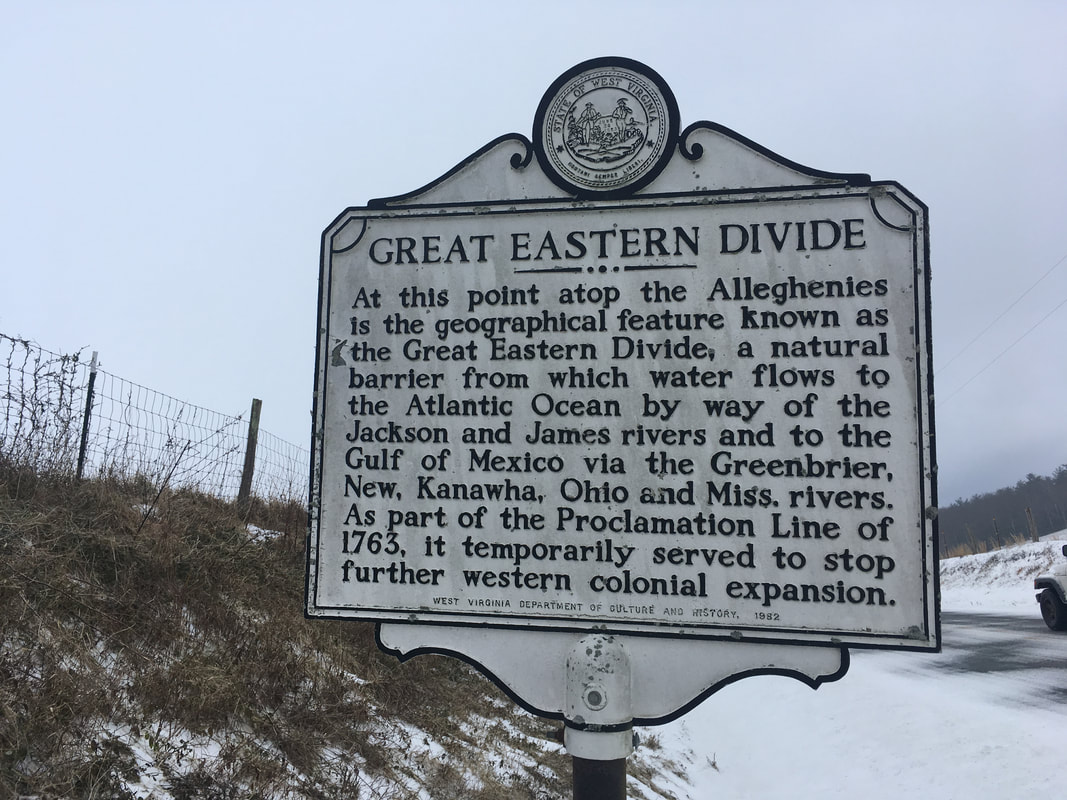

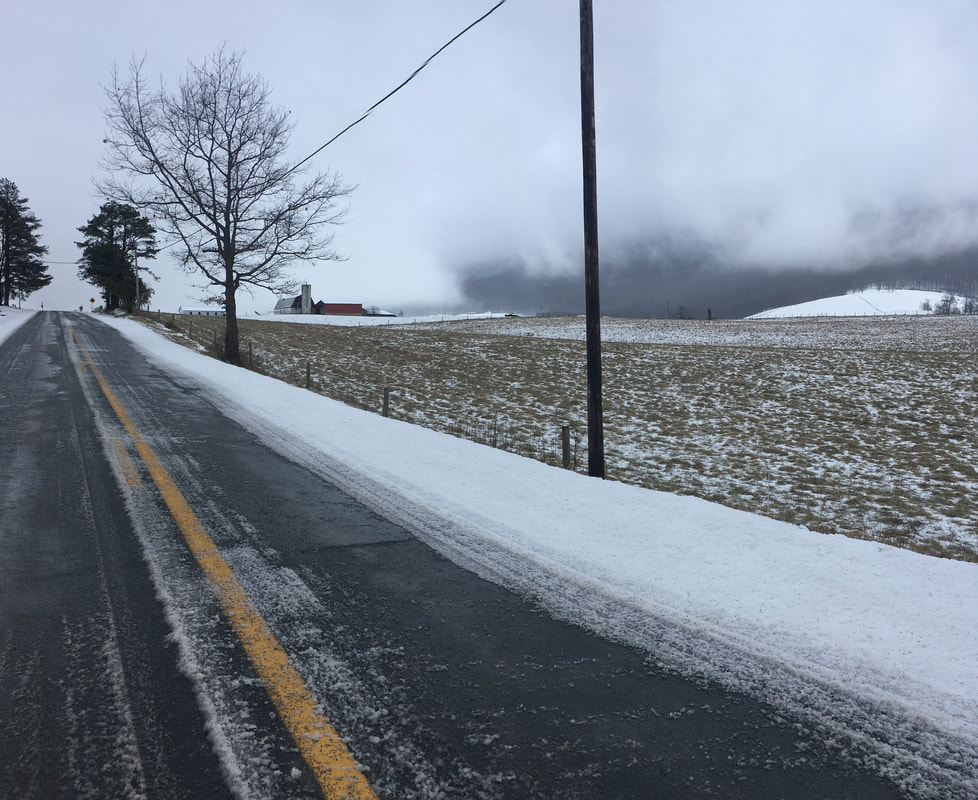

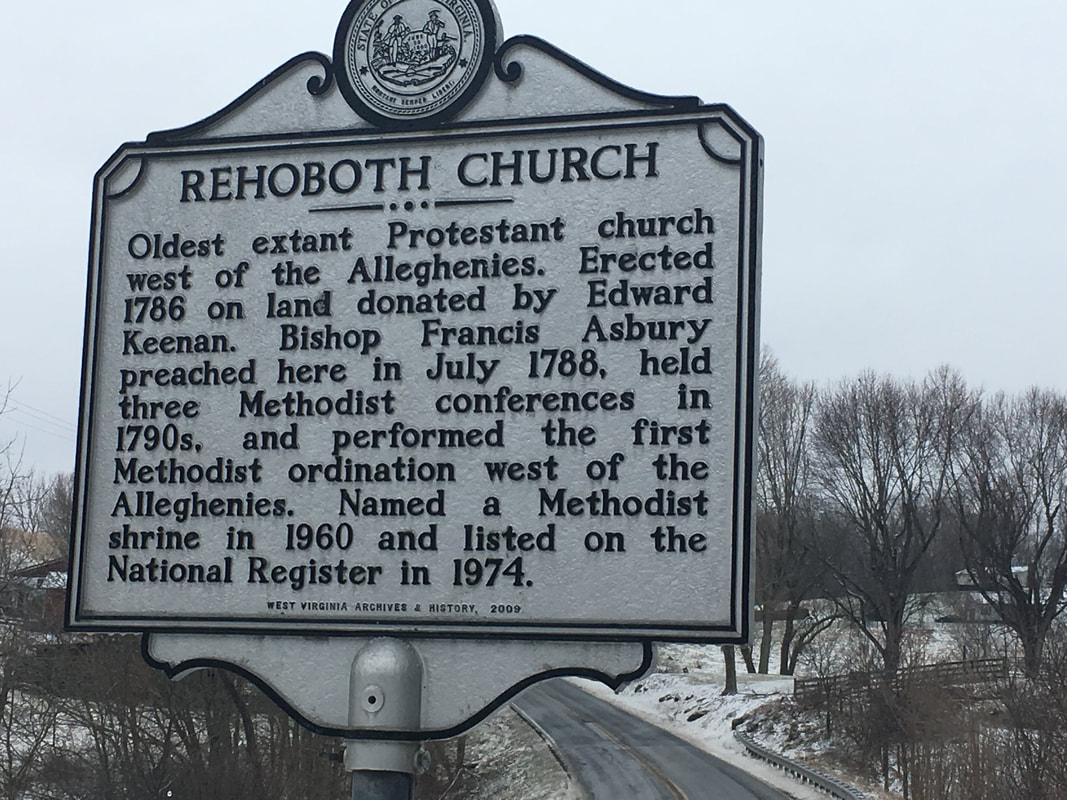

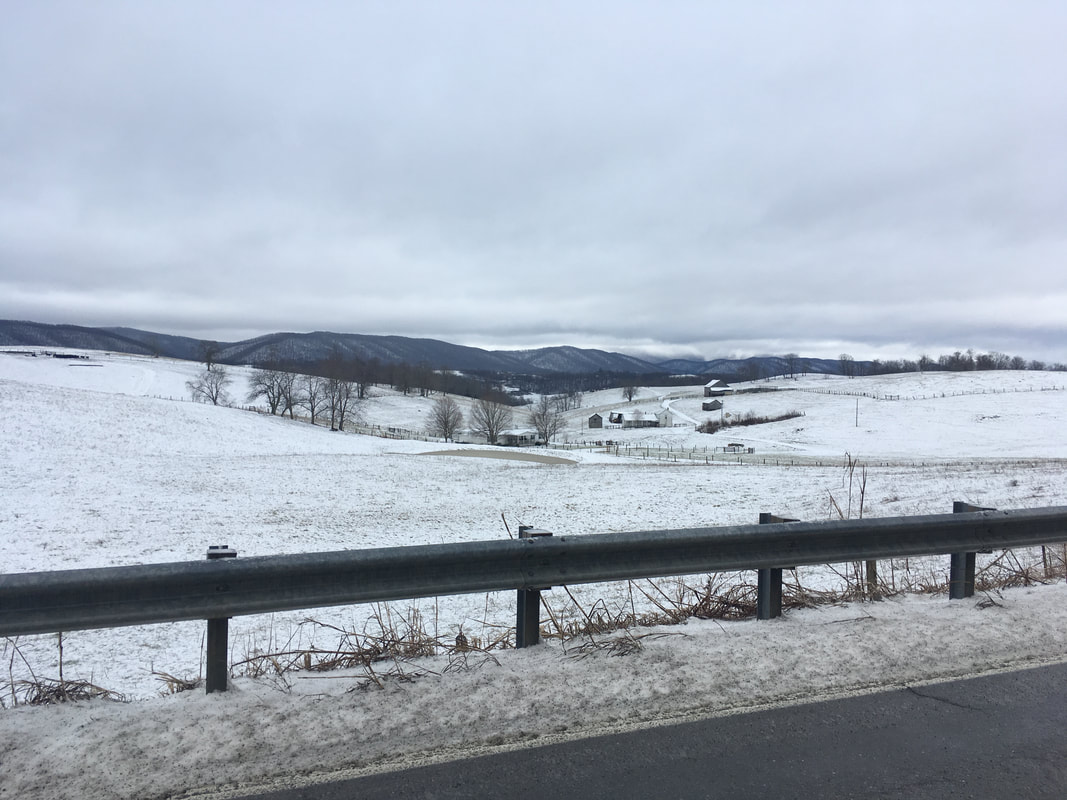

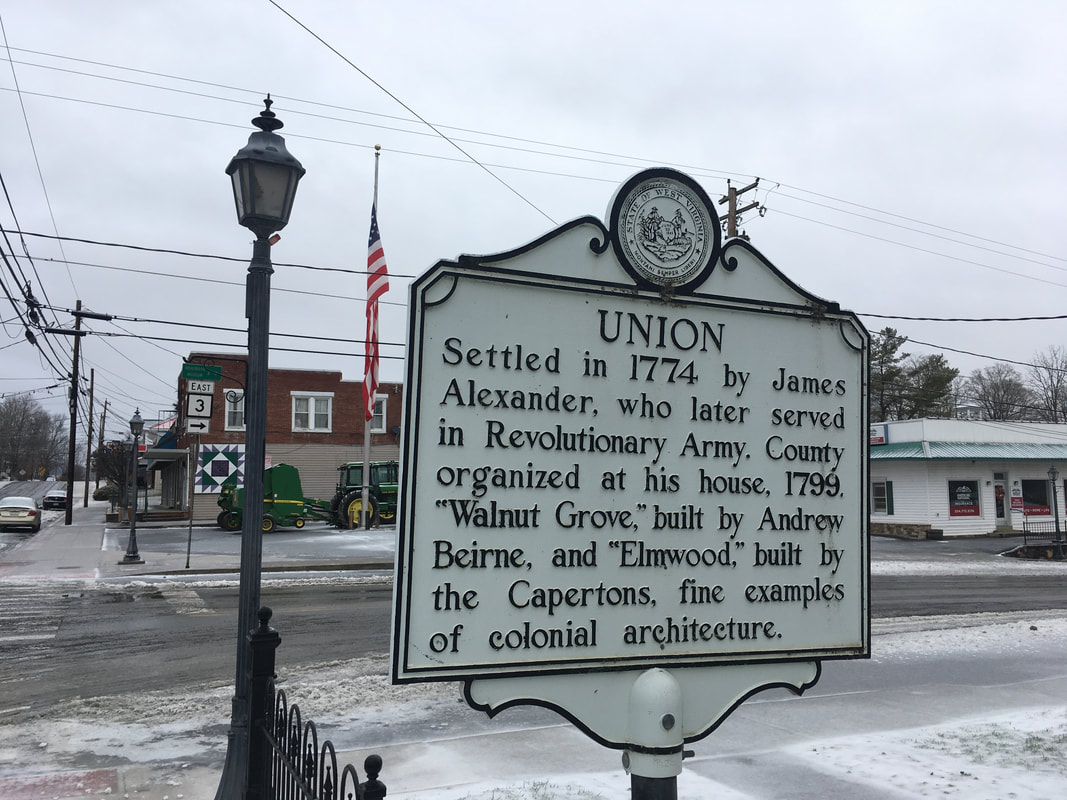

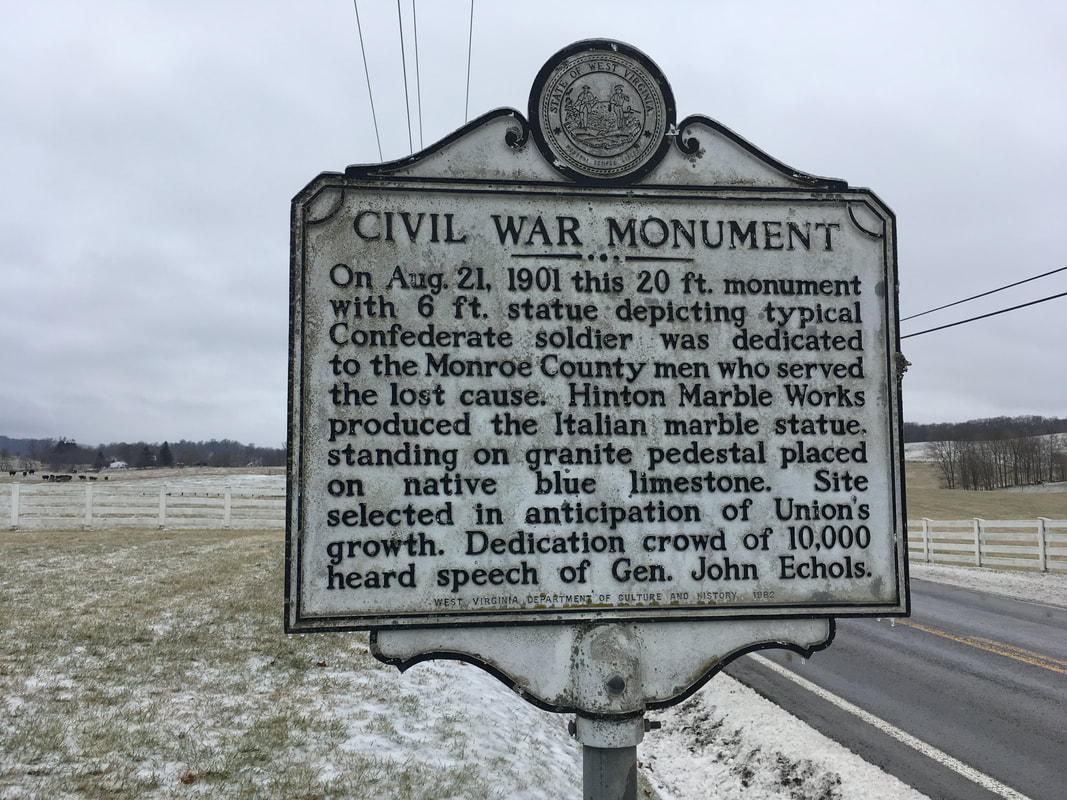

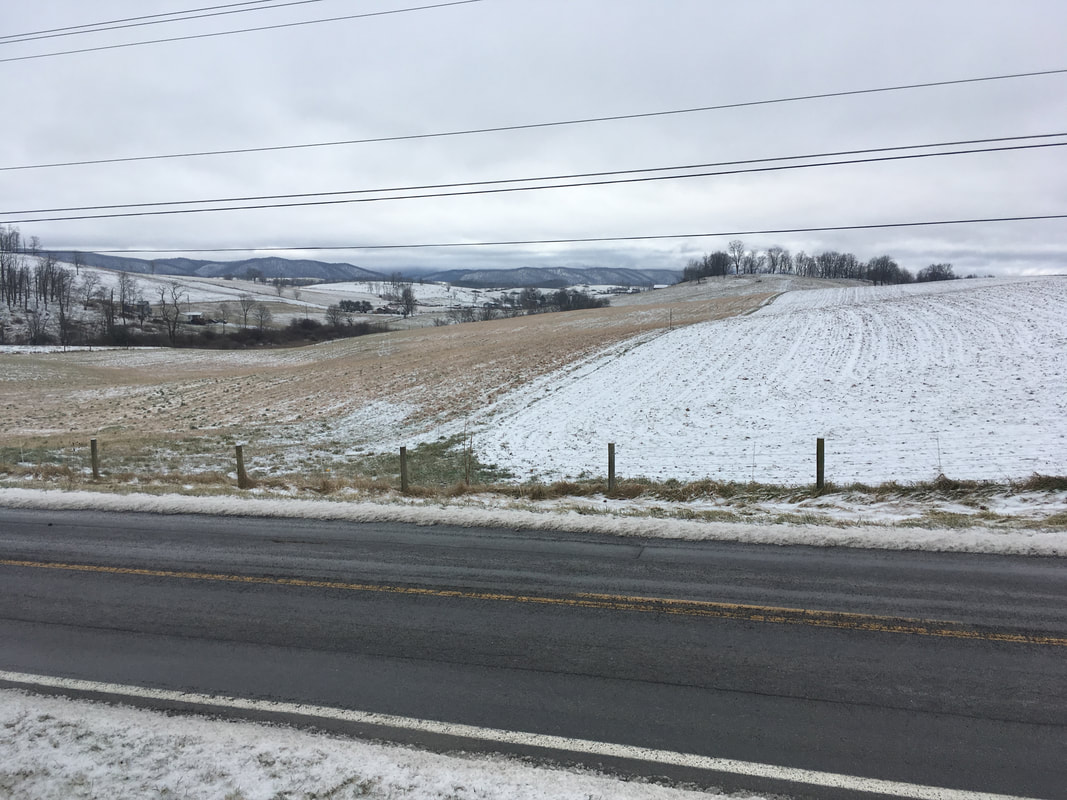

From time to time I venture off the Jamison Family Farm and make my way into West Virginia to a town called Union. Year round - the drive is spectacular and today was no exception. The roads are straight, rolling and lined with farms and mountains - it is truly a time for clear thought and meditation for all things worth pondering. We had snow and ice last night and with Church canceled, I got myself into the Jeep and began the drive... Soon - I crossed the Great Eastern Divide. Just beyond the slight hill ahead - on which this sign rests, the valley and scenery fully open... Looking over my shoulder... As I continue my trek towards Union, I come to a place called Gap Mills... In Gap Mills, there is a terrific store that sells all sorts of nuts, chocolate, deli-meat, flour - cheese and more. It is worth a stop - but they are not open on Sunday... The store is called Cheese N More... Moving along on Rt-3 West... The scenery continues... Another stop along the way (when it is warm and snow/ice free) is the Rehoboth Church. It is hard to believe this area was once the Western edge of the frontier. Continuing along a soothing, meditating, stress relieving drive... One soon finds themselves upon Union... An integral part of our haying is soil inputs based on soil tests. We send the soil samples to Va Tech for analysis and with their recommendations, we buy our lime and fertilizer from Mountaineer Farmer Center in Union. They are great folks with whom to do business. Throughout the drive - there are many quilts... At the end of the journey to Union - I recommend taking time to break bread. Sometimes I stop at the Korner Kafe or the Kalico Kitchen... Today I had a relaxing breakfast just beyond Union in a place called Pickaway - at a resturant called the Pickaway Pickins... As you begin to exit Union - to the North, there is the Union Presbyterian Church with wonderful stained glass and a beautiful sanctuary with a balcony. Behind the Church to the left is a Civil War monument... If you'd like a good read, I recommend buying, or better yet, subscribing to the weekly news paper, The Monroe Watchman. After the drive to Union and a big breakfast - for desert, make a U-turn and enjoy the scenery again as you make your way back to - The Jamison Family Farm.

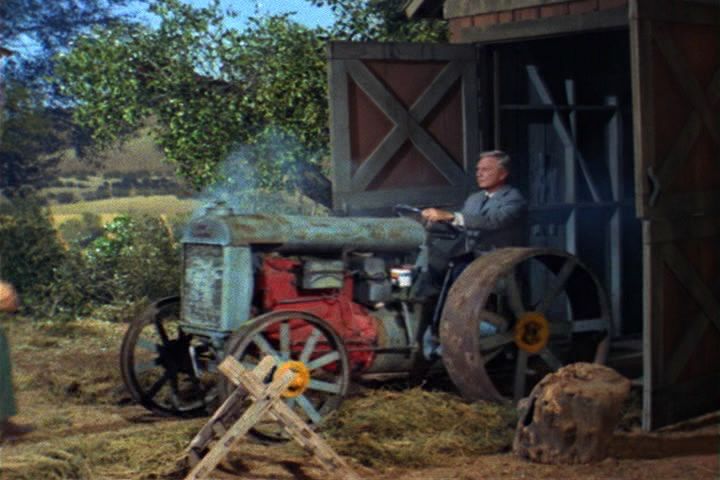

Today is January 1st 2019. Happy New Year! Probably shouldn't say, "good to see 2018 in the rear view mirror" as who knows what is ahead for 2019, but I am glad to see the start of 2019 and a new year on the Jamison Family Farm. Spent some time today there and found ourselves cutting and gathering a bit of firewood. Things are drying out a bit; the wind was brisk and it felt unseasonably warm. All in all, it was a calm, uneventful day - a nice way to start off 2019. The tree we cut shown in the picture above was in the Bull Pasture. It has been dead for a few years and made a steady contribution of dropped limbs and twigs in that field, so we cut it for firewood. The trunk is left high as we will put a bull dozer against it to get the stump out and rid the field of the whole tree. We are hopeful for 2019 and if the weather cooperates, expect a bumper crop of hay. Additional acreage is going to be added and in addition to our Timothy, we expect to plant some annual Teff grass. We will build more kicker racks on our existing hay wagons to go along with our baler mounted kicker... John Deere calls it a " #42 Ejector". All I know is that it's a massive labor savor as it eliminates a person on the wagon stacking in the hottest of hot days. Depending on the size, we can fill a wagon with anywhere from 130 to 150 square bales of hay in 20-30 minutes. May the Hay Dog is glad to see 2019 too. Dressing up for Christmas 2018 just about wore her out... Field ready... Looking forward to making First Quality Hay in 2019 and wish everyone a very... Happy New Year!!!We have finished haying for 2018, things have calmed down - except for the coming aftermath of Hurricane Florance. We're expecting rain and some wind, but have our fingers crossed there will be no damage. I have one field, "The Bull Pasture" that can get some water in it from Potts Creek running along side. Activities going on at the Jamison Family Farm are multifold, we will be taking soil samples of all our fields and applying lime (as necessary), certainly potassium (sometimes referred to as potash) and phosphorus. It's good to also apply a little nitrogen in the fall as it promotes tillering - read leafy material. We can't get straight phosphorus from our supplier, but they have what is called DAP - diammonium phosphate. Fertilizer is typically identified by numbers, for example, most are familiar with a bag of 10-10-10. That bag, in order of the numbers, has 10% nitrogen (N), 10% phosphorus (P) and 10% potassium (K). The DAP we apply is 18-46-0, so we get 18% nitrogen along for the ride when we apply it - scratching the itch for fall applied nitrogen, while filling the need for phosphorus. The "10"; we will continue to clear with hopes we can plant Teff in it next year. Our field of timothy on Crown Hill appears strong; we should get a bumper crop out of it in 2019. We thought we'd have a new barn of some sort in 2018, but for various reasons, that did not happen. Clearing the "10" and adding hay shelter space is our highest priority going into the Spring of 2019. On another front, our International Harvester Farmall 756 is likely to get an engine rebuild, wide front end and a few other upgrades. Pic of 756 below... If you've ever visited the farm or bought hay from us, often we point beyond the "big house" to the "hill". That is where Crown Hill resides, along with many other fields - all of which, to the extent we can safely put a tractor on them, will become hay fields. When I was on the farm the other day, I took this panoramic picture looking down from the "top" of the hill. Crown hill is just ahead center-left. If you could fly beyond those mountains straight ahead - you would land in Covington. Without a doubt, 2018 has been both a very difficult, yet a very successful year haying. We struggled with unrelenting rain - causing delays and hampering dry down, etc. We also had our share of equipment breakdowns. While we made more hay than we ever have, we only made about 60% of what we could, but hay we did make tested-out extremely well. Some rain delays caused hay to become overripe, as well as, letting weeds grow-in. We refuse to bale trash hay and pass it off as "horse quality hay", and several acres were let go to seed and bush hogged down. We do have some "goat" customers on a budget and any hay we deem not "horse quality" in our stack, they are glad to take at a reduced price. It helps them and helps us empty our barn. The pic below is our Massey Ferguson model 50 diesel taking down what would have been a nice timothy field had the weather cooperated. The good news with that field is - the timothy went to seed, so we got something out of it. I'll be writing more blogs, putting up more pics and adding a few haying videos as we roll out of Summer into Fall and Winter. While things may be slowing down a bit, we continue to pursue First Quality Hay.

All of our test results for our first cutting hay are in hand. May the Hay Dog has evaluated and gives them 2 bones up...

With each cutting of hay, we take core samples and send to Equi-Analytical for testing. We use wet chemistry via the 603 Trainer test. Below is the description of what results are to be gleaned from Equi-Analytical's website: "(603)Trainer - utilizes traditional analytical methods to determine protein, fiber, carbonhydrates and minerals. Includes moisture, dry matter, digestible energy, crude protein, estimated lysine, acid detergent fiber, neutral detergent fiber, Ethanol Soluble Carbohydrates (ESC), Water Soluble Carbohydrates (WSC), starch, non fiber carbohydrates (NFC), calcium, phosphorus, magnesium, potassium, sodium, iron, zinc, copper, manganese, molybdenum." All in all we submitted five tests. We test our hay for each field and within a field, we will take multiple tests if the hay is cut on a different day - even if it is a few days away. Our hay is low in sugar (ESC+starch), low in potassium and iron. A summary range across a few test result items - all based on Dry Matter basis: Crude Protein: 8.9 - 14.9% ADF: 39.0 - 42.3% NDF: 63.4 - 70.1% ESC (Simple Sugars) : 4.3 - 8.2% Starch: 0.2 - 0.8% Note - none of the combinations of ESC + starch on an individual test exceeded 8.4% Potassium: 1.86 - 2.51 ppm Iron: 84 - 165 ppm RFV: 74 - 86 All hay is sorted/stored based on test results such that one can pick/choose their hay with respect to a specific forage test. If you are interested in what we think is some nice timothy hay - we'd appreciate your business. If you want copies of our test results, let us know. For test results and/or questions - email: [email protected] Thanks! The Jamison Family (and May the Hay Dog... )  We start cutting hay... Weather permitting. Cutting will start on Wednesday May 23rd and we will bale into and through Memorial Day weekend. First bales maybe Friday the 25th, but certainly Saturday May 26th. Again - the weather can throw a wrench into everything. F.A.Q's...I get a lot of questions regarding the business side of buying hay from us. Here are a few bits...

1. Can I pick up hay the day you bale it. Ans: Yes. We have a spot where we will bring our hay wagons, hand down the hay from them for you to load. 2. How much do your bales weight? Ans: 35-45 lbs typically. Weight varies with humidity the day we bale. 3. How long are your bales? Ans: 30 inches, give or take a couple inches either way. 4. How tight are the bales. Ans: We bale a tight bale, no puff balls or banana bales in our stacks. 4. Will you take a check. Ans: We prefer cash (hard to bounce a dollar bill), but there are exceptions. Receipt provided. 5. Sales tax - really? Ans: Yep - the Commonwealth of Virginia wants their cut (no pun intended). 6. Do you deliver? Ans: No - we simply don't have the trucks/trailers to deliver. Some folks bring their horse trailer, others hire a neighbor with a trailer and/or truck and some have rented a Uhaul for a day. 7. Will you hold hay? Ans: Generally No. We've been stiffed by more than one customer that had us hold hay on the promise they'd pick it up. Not only did they not come for the hay or let me know they weren't - I turned away customers with cash who bought elsewhere. 8. How much do you charge per bale? Ans: For 2018, no more than $5.00 per bale. This pricing reflects the shorter length of 30 inches. Ultimately pricing will be set by the hay quality and forage test results. If you come out for hay the day we bale we will give a 25 cent discount per bale. Fingers crossed for a great haying season! Email with questions to [email protected] or call us at (540) 597-8147. Thanks! The Jamison Family |